Tuning into 110 years of tradition

Celebrating Bow Brand’s unwavering loyalty to King’s Lynn and following its fascinating journey, from making sausage casings to gracing the Wimbledon courts, concert halls and palaces

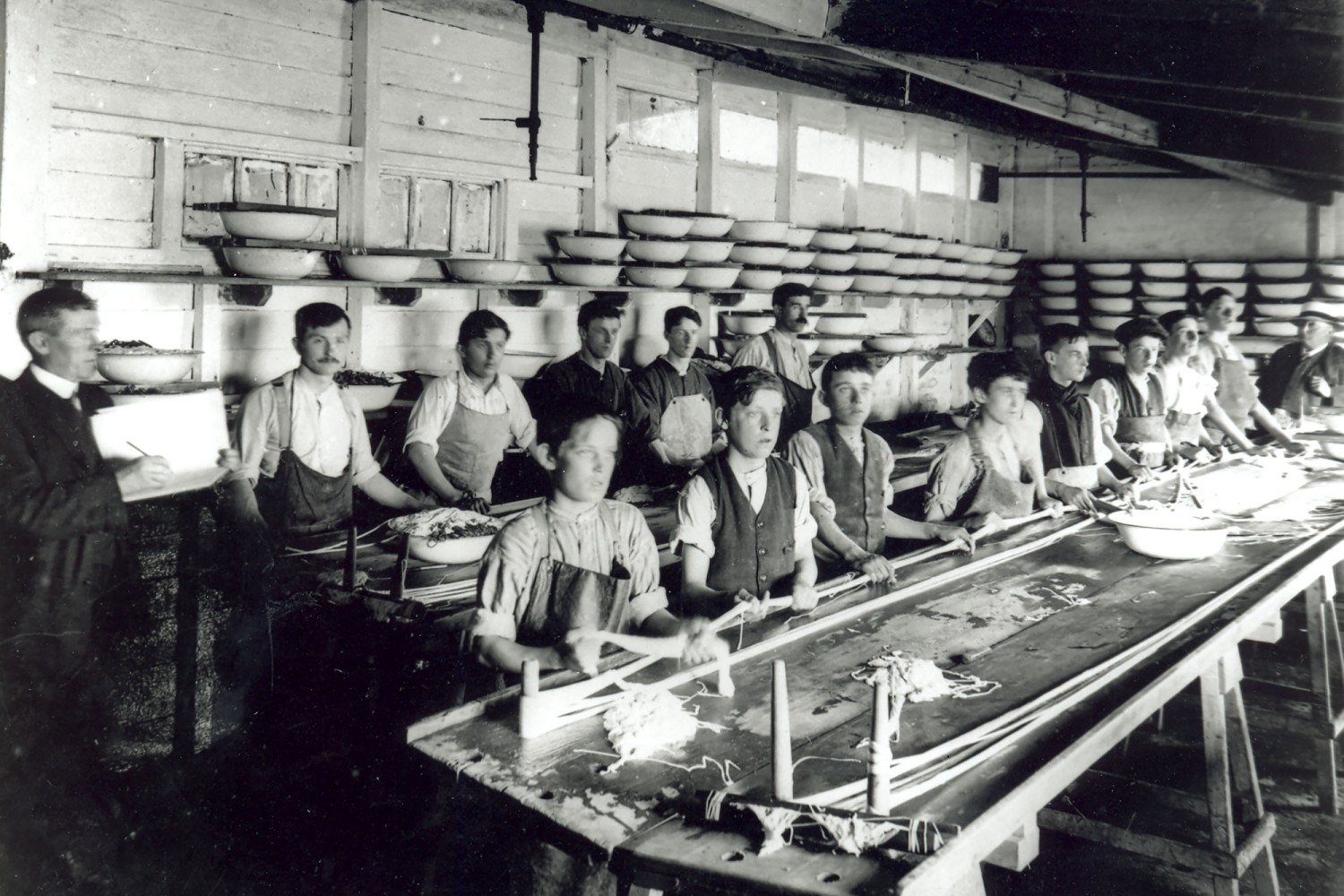

ABOVE: Gut strings being spun by young workers at the Bow Brand factory in the early 20th century. Female workers sorting, grading and measuring gut, a somewhat unpleasant yet valuable source of employment at the time.

In an unassuming factory tucked away in a hidden corner of King’s Lynn, the last large natural gut string-making manufacturer in the UK is nurturing an age-old art and making hearts sing.

Every string produced by Bow Brand is a testament to over a century of expertise, respecting materials and traditions passed down through generations. Skilled artisans still work to meticulously handcraft each string, endowing musical instruments with their unique voice and sending the smooth sounds of Bow Brand to stages, schools, colleges and concert halls across the globe.

The company’s committed director, Ana Salvi Maddox, proudly pours her passion for music and history into preserving the art of string making in Norfolk. As a member of the renowned Salvi family, she continues the work of her father, Victor Salvi, a celebrated harpist whose legacy endures through his world-famous harp making business in Italy.

“Upon arriving in King’s Lynn, I was captivated by the town’s rich heritage and I love that Bow Brand is an intrinsic part of that,” says Ana. Her dedication has helped Bow Brand to become a preferred supplier for some of the world’s finest luthiers and musicians, elevating the company’s reputation further.

Among the many accomplished artistes using strings crafted in King’s Lynn is the esteemed Welsh harpist Catrin Finch, who was appointed Royal harpist in 2000 when the then Prince of Wales revived the position for the first time since Queen Victoria’s reign. Four years later, Salvi created a unique gold leaf harp for the current King, proudly utilising fine Bow Band strings.

Ana’s family assumed ownership of Bow Brand in the mid-90s, but the company’s journey began in 1915 when German-born Johannes Hemeter relocated from London to establish a gymnasium in Broad Street along with a business manufacturing sausage casings and gut strings. He chose the Highgate site for its easy access to a constant source of water provided by the nearby Gaywood River and for its proximity to a slaughterhouse, essential for supplying the animal by-products for what became commonly known as ‘the gut factory’.

While the factory provided welcome employment at the time, the work environment was reportedly harsh, with rows of female factory floor workers standing in bowls of hot water to keep warm.

Within months of Hemeter and Sons being commissioned to make sutures for the army in the First World War, Johannes died in a tragic horse and cart accident. His dedicated sons Charles, Stanley and John (by then a war hero) took over the family business and initiated a return to producing strings for musical instruments and tennis racquets. Had Johannes lived, he would have been proud to see his company appointed as the Official Wimbledon Stringers.

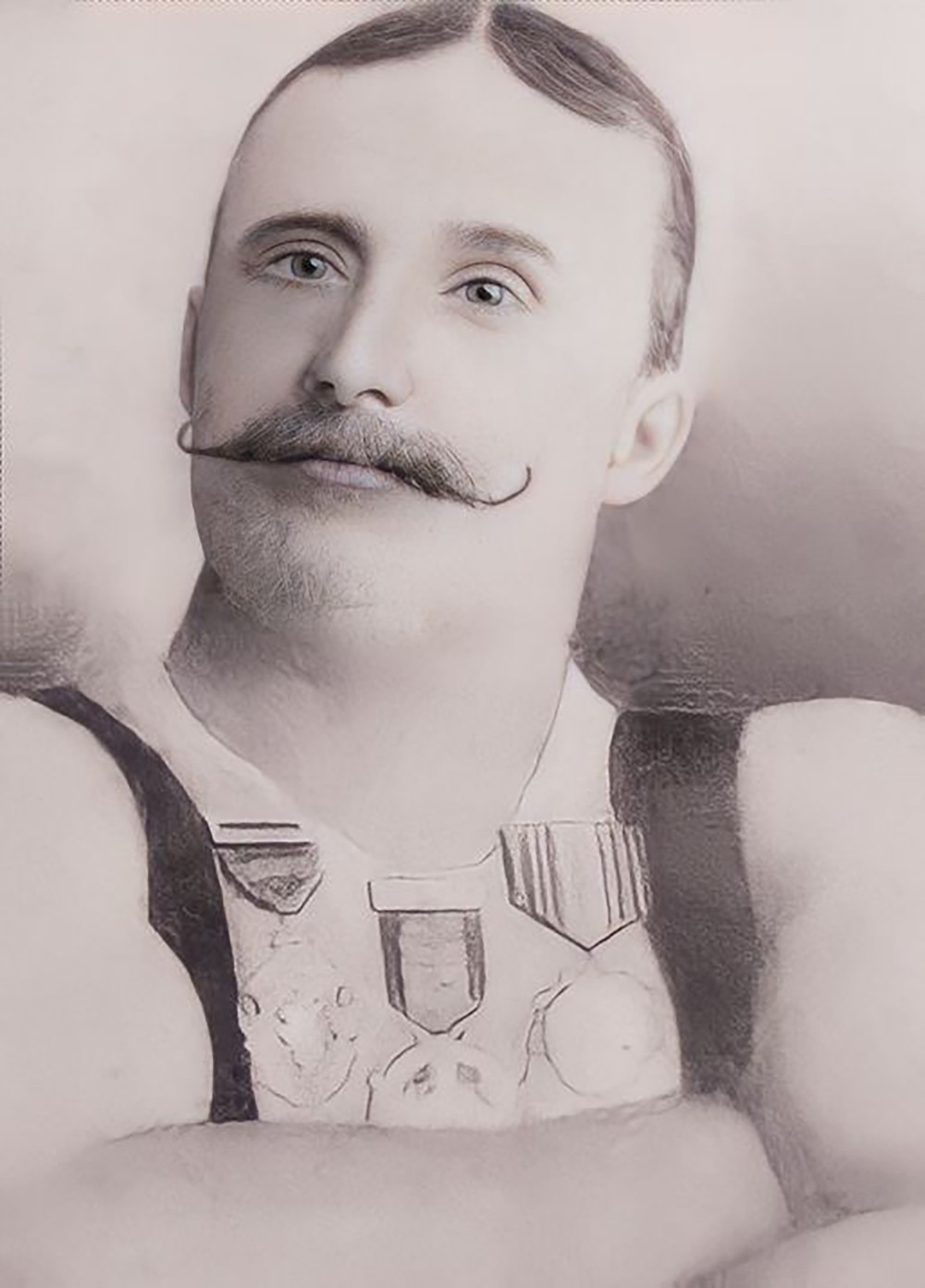

ABOVE: Bow Brand Director Ana Salvi Maddox is proud of her family’s remarkable harp-making heritage and continues to play an instrumental role in maintaining the company’s reputation for excellence (above left). German-born Johannes Hemeter moved to Lynn from London and opened the Bow Brand factory in 1915.

In this role, a team travelled from King’s Lynn to the prestigious tournament each summer to string and repair the racquets of the tennis elite. This was a significant honour for a small King’s Lynn factory and autographs of famous players like Venus Williams, Steffi Graf and Andre Agassi still take pride of place in the Bow Brand canteen.

The Wimbledon link continued into the 1930s when the business was bought by Cordes Harmoniques Babolat & Maillot, founded in Lyon in 1875. Babolat is the oldest racquet company in the world, and it became known as Bow Brand.

By the time today’s owners took over in 1995, the abattoir had closed, but Bow Brand remained official Wimbledon stringers until 2010.

“That was when our main focus turned to music strings,” Ana explains. Emphasising her enthusiasm for the quality of natural gut materials, she adds, “Synthetic strings might mimic some of the characteristics but nothing else can create the tonal richness of gut strings.”

The manufacturing process is intricate and precise, starting with the selection of the finest raw material, specifically the serosa from the outer layer of the intestine. Instead of being discarded by the meat industry, it can become something beautiful through string-making.

“It may seem surprising given my vegetarian lifestyle, but I believe using natural gut in string-making honours an animal’s life through the power of music,” Ana adds.

Staying true to this ethos, the serosa is sourced exclusively from suppliers with the highest animal welfare standards and, because it is biodegradable, it offers musicians an eco-friendly alternative to synthetic strings.

These natural products, combined with authentic techniques, inevitably place the variables of nature at the helm of the labour-intensive creative process. This involves 30 individual steps over at least nine weeks to wash, spin, dry and finish each string before they are shipped to distributors worldwide.

“While our achievements are a source of great pride, I find it sad that many remain unaware of our contributions or the factory’s role in local industrial history,” Ana concludes. “It’s a story that needs to be told and celebrated.”

You can discover more about Bow Brand by visiting bowbrand.com and follow the company’s journey on Facebook and Instagram.